The Dimension Values Are Oriented to Be Read From When Using Unidirectional Dimensioning Methods

Alphabet of Lines

What is the chief image, which we are using in all our projects, designs, drawings?

Information technology is a line!

In Graphics Communication practice there is the whole collection of dissimilar lines, which are used for drawing purposes.

The alphabet of lines is a set of standard line types established by the American National Standards Institute (ANSI) for technical cartoon. The alphabet of lines and the guess dimensions used to create different line types, are referred to every bit linestyles when used with CAD.

The standard line types used in technical drawings are

Center lines are used:

- to represent symmetry,

- to stand for paths of move,

- to mark the centers of circles and the axes of symmetrical parts, such as cylinders and bolts.

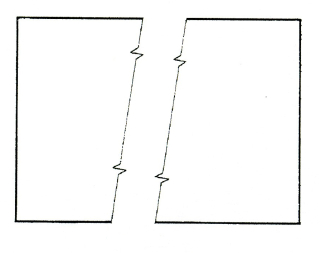

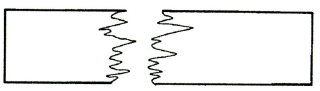

Break lines are used to testify where an object is broken to save cartoon space or reveal interior features.

Break lines come in two forms:

- a freehand thick line, and

- a long, ruled thin line with zigzags.

Dimension and extension lines are used to indicate the sizes of features on a drawing.

Section lines (hatching) are used in section views to stand for surfaces of an object cutting by a cutting plane.

Phantom lines are used to represent a movable feature in its different positions.

Stitch lines - to indicate a sewing or stitching procedure.

Visible lines are used to represent features that tin can be seen in the current view.

Hidden lines, equally y'all already know, are used to represent features that cannot be seen in the current view.

Cutting plane lines are used in section drawings to evidence the locations of cutting planes.

In that location are also lines used in some particular cases:

Concatenation lines - to indicate additional treatment for a surface.

Symmetry lines - as an axis of symmetry of a particular view.

While preparing drawings you must follow the rules established for the line technique.

Each line should have i of the two thicknesses, thick or thin, and the ratio of the thicknesses must be non less than 2:i. In many textbooks (especially, of the U.s. authors) you will come up across the thicknesses of lines: 0.three mm and 0.6 mm. In general cases it is good enough in practical work.

The alphabet of lines assigns specific thickness to each line and it cannot be changed arbitrarily.

In cases where other than shown types of lines are used for special drawings (for case, electric drawings, pipeline diagrams, or building drawings) the conventions adopted must be clearly indicated by reference to specific standards or by notes on the drawings.

For all views of 1 slice or assembly to the same calibration, the thickness of the lines should be the same. Medium and extra-thick lines should be used just in special cases.

The minimum infinite between parallel lines should never be less than twice the thickness of the heaviest line. Information technology is recommended that these spaces be 0.vii mm or greater.

In finish views of circular features the point of intersection of two eye lines should be shown by two intersecting short dashes, except for very small circles, as shown:

Break Line are used to shorten the view of long uniform or tapered sections, or when merely a fractional view is necessary, and are used on both particular and associates drawings.

The thin line with freehand zig-zags is recommended for long breaks and may be used for solid details or for assemblies containing open space.

Thick freehand lines are used for short breaks

and the jagged line for forest parts.

The special thick break lines shown for cylindrical and tubular parts are useful when an end view is not shown, simply otherwise the thick freehand break line is adequate.

Note that all these intermission lines were designed for preparing drawings in the sometime-fashioned manner past using a typhoon lath. Sometimes engineers and designers nevertheless piece of work on drawings with pencils and rulers. Even so, mod 3D CAD software, which prevails in our days, can offer other line types for the suspension lines in the figurer-based drawings.

Dimensioning practice

Once the shape of a function is defined with an orthographic drawing (i.e., in projections), the size data is added in the course of dimensions.

Dimension elements

Dimensioning a drawing likewise identifies the tolerance (or accuracy) required for each dimension.

- Dimension — the numerical value that defines the size, shape, location, surface texture, or geometric characteristic of a feature.

- Basic dimension — a numerical value defining the theoretically verbal size, location, or orientation relative to a coordinate system. Basic dimensions are enclosed in a rectangular box & have no tolerance.

- Reference dimension — a numerical value enclosed in parentheses, provided for data merely.

- Dimension line — a thin, solid line that shows the extent and direction of a dimension.

- Arrows — symbols at the ends of dimension lines showing the limits of the dimension, leaders, and cutting airplane lines.

- Extension line — a thin, solid line perpendicular to a dimension line, indicating which feature is associated with the dimension.

- Visible gap — there should be a visible gap of 1 mm between the feature's corners and the end of the extension line.

- Leader line — a thin, solid line with arrow drawn nether an bending & indicating the feature with which a dimension or notation is associated.

- Limits of size — the largest adequate size and the minimum acceptable size of a feature.

- Plus and minus dimension — the allowable positive and negative variance from the specified dimension.

- Diameter symbol — a symbol indicating that the dimension shows the bore of a circle. The symbol used is the Greek alphabetic character phi Ø.

- Radius symbol — a symbol indicating that the dimension shows the radius of a circle. The radius symbol used is the capital letter R.

- Tolerance — the corporeality that a particular dimension may vary.

Basic concepts and principles

- The unit of measurement of measurement for dimensioning should be in accordance with the policy of the user. On a drawing for use in American industry for manufacturing, all dimensions are in inches, unless otherwise stated.

- Most countries exterior of the United States, including Canada, use the metric system of measure, or the international system of units (SI), which is based on the meter.

The common metric unit of mensurate on engineering science drawings is the millimeter, abbreviated equally mm.

Sometimes, you will have to identify dimensions in two units simultaneously!

Dimensions should exist placed in the nigh descriptive view of the feature.

If the view is overcrowded with unlike dimensions, 2 and more separate drawings with the aforementioned view tin be produced.

Dimension text placement

Text of the dimensions can be placed in dissimilar ways:

- dimension inside the extension lines, with arrows within or outside; and

- dimension outside the extension lines, with arrows over again inside or outside.

Where space is limited extension lines may be drawn at an angle:

Extension lines should non cross dimension lines, and they should avoid crossing other extension lines whenever possible. When extension lines cross object lines or other extension lines, they should non be cleaved. When extension lines cross or are shut to arrowheads, they should exist broken for the arrowhead.

Arrowless dimensioning

To avert having many dimensions extending away from the part, arrowless dimensioning may be used.

- the "zero" lines represent the vertical and horizontal datum lines,

- each of the dimensions shown without arrowheads indicates the distance from the zero line.

- There shall never be more than than one zero line in each direction.

- Arrowless dimensioning is used for locational dimensions for a series of features such as holes and slots.

All dimensions and note text must be oriented to read from the bottom of the cartoon. This is called unidirectional dimensioning.

The aligned method (where text is placed parallel to the dimension line) may be seen on older drawings or on architectural drawings but is not approved by the current ANSI standard.

Group dimensions

In standard practice, dimensions are grouped on a cartoon for compatible appearance.

Avoid using object lines as extension lines for a dimension.

Dimensions must be kept outside the boundaries of views, wherever applied.

Dimensions tin can be placed in series and parallel.

- When a series of dimensions is applied on a signal-to-signal basis, information technology is referred to every bit chain dimensioning .

The showtime dimension in a raw should be stuck to a base line.

Disadvantage of this system: information technology may result in an undesirable accumulation of tolerances betwixt individual features.

- When several dimensions start from a mutual reference point or line, the method is referred to as common-betoken, or parallel, dimensioning .

The reference line may exist an extension of the outline of the origin, a base of operations line, or a system line.

The base surface is the external surface of the function, which must be machined first.

Dimensions can be placed in parallel or in serial, but in all cases, they should exist related to the base (datum) surface.

Stagger dimensions

The general practise is to stagger the dimension text on several parallel dimensions.

Size dimension

The dimensions can exist classified by types of size:

- Horizontal — the left-to-right altitude relative to the cartoon sheet. Here the width is the merely horizontal size dimension.

- Vertical — the upwards and down distance relative to the drawing sheet. Here the peak and the depth are both vertical dimensions, even though they are in two different directions on the part.

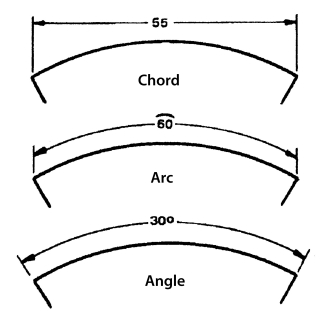

- Diameter—the full distance across a circle, measured through the middle.

- Radius—the distance from the center of an arc to any point on the arc. Radius is unremarkably used on arcs less than one-half circles.

Location and orientation dimensions

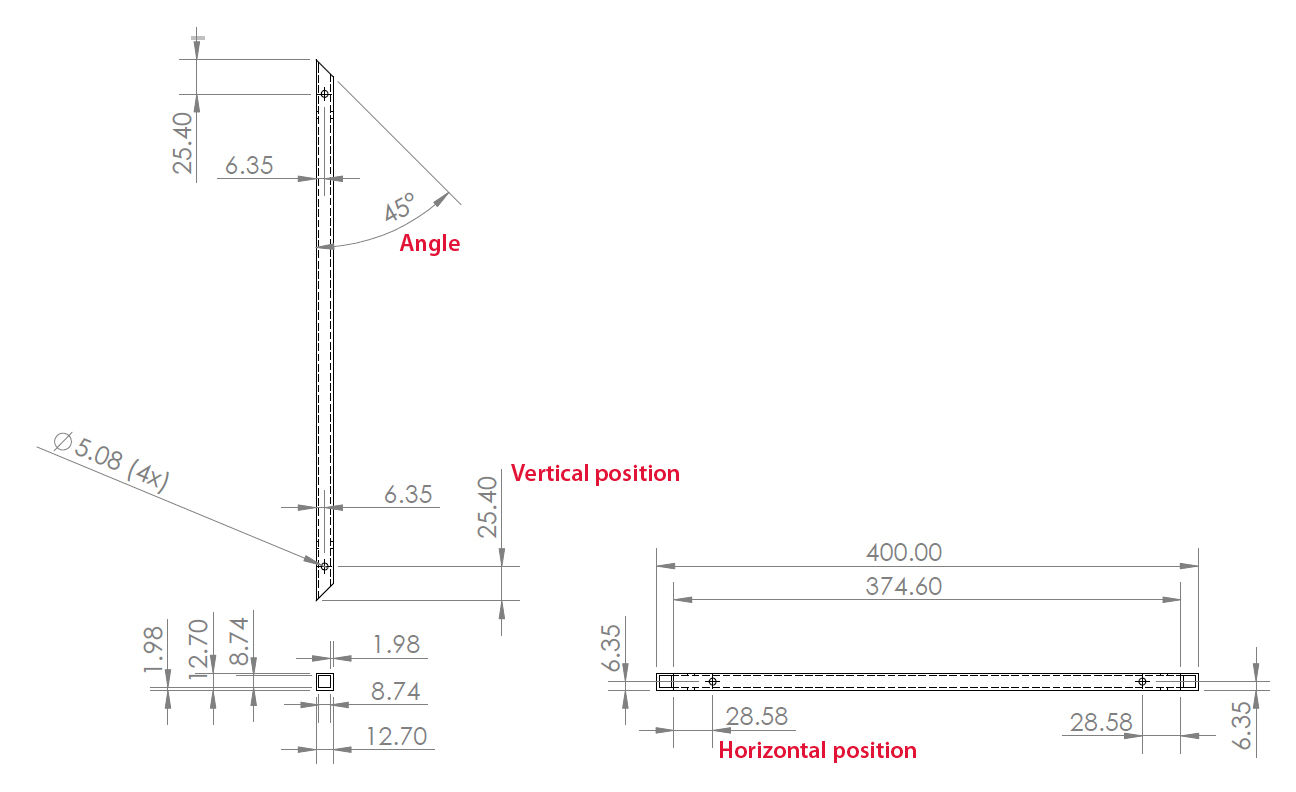

The dimensions can exist classified by type of location or orientation:

- Horizontal position – locates the position of the characteristic in horizontal direction with respect to a base;

- Vertical position – locates the position of the characteristic in vertical direction with respect to a base;

- Angle – gives the bending between the horizontal aeroplane and the sloping surface.

Angular units

- Angular dimensions are shown either in decimal degrees or in degrees, minutes, and seconds.

- Where only minutes and seconds are specified, the number of minutes or seconds are preceded by the 00.

Information technology is likewise skillful to have an isometric view of the part on its drawing. Not mandatory simply preferable for complex parts.

No dimensions should be shown on isometric view. Calibration must exist shown if it differs from the general ane.

Item dimensioning (How to dimension various features)

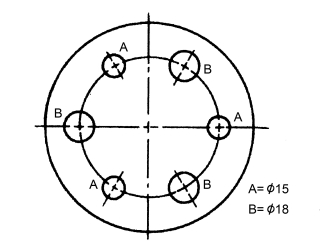

- Holes are typically dimensioned in a view which best describes the shape of the hole. Diameters must be dimensioned with the bore symbol preceding the numerical value. When holes are dimensioned with a leader line, the line must be radial.

A radial lin e is ane that passes through the middle of a circumvolve or arc if extended.

- Symbols may be used for spotface, counterbore, and countersunk holes. These symbols always precede the diameter symbol.

The depth symbol may exist used to indicate the depth of a hole. The depth symbol is placed preceding the numerical value.

- When the depth of a bullheaded hole is specified, it refers to the depth of the total diameter of the hole.

- Chamfers are dimensioned by providing either an angle and a linear dimension or by providing two linear dimensions.

Chamfers of 450 may exist specified in a note.

- Slotted holes may be dimensioned any of several means depending on which is nearly appropriate for the application.

- The slope of a line or flat surface tin can be specified:

(a) as a ratio combined with the slope symbol; (b) by the angle; (c) by the dimensions showing the divergence in the heights of two points from the base of operations line and the distance between them.

- Dimensioning chords, arcs and angles

- Keyseats and keyways, which are fastening devices, are dimensioned in a particular way, considering they nowadays some unusual bug.

The acme of the keyseat itself is non dimensioned because, once the height of the shaft is cut away, at that place is no feature left to measure out.

Also the dimensions are unilateral:

- for the keyseat, the dimension is a minimum;

- for the keyway, the dimension is a maximum.

This is to ensure an interference once the key is inserted between the parts.

Dimensioning repetitive features

- Repetitive features and dimensions may exist specified by the use of an "X" in conjunction with the numeral to indicate the " number of times " or " places " they are required. A full infinite is left between the "X" and the feature dimension.

An "Ten" is sometimes used to indicate " Past " between coordinate dimensions specified in note form. A half space is left in this case betwixt the "X" and the dimensions.

To avoid repeating the same dimension or to avoid long leader lines, we may utilize reference letters in conjunction with an explanatory table or note.

- Identification of similar sized holes

- Dimensioning gears

A gear is a toothed-wheel mechanical device used to transit power and motion between machine parts. Typically a shaft is used to both utilise and receive ability from the gears.

When 2 gears of different sizes mesh, the larger is called the gear and the smaller is the pinion.

Normally, gear drawings include a table of information, called cutting data, for manufacturing. A detail drawing of a gear would besides include other dimensions not plant in the table (root diameter, diameter bore, keyway dimensions).

Alternatively, gears and splines may be shown with a solid line representing the bones outline of the part, and a lighter line representing the root of the teeth.

The pitch line may be added using the standard eye line. This is the aforementioned convention as used for spiral threads.

Source: https://www.mcgill.ca/engineeringdesign/engineering-design-process/basics-graphics-communication/principles-dimensioning

Post a Comment for "The Dimension Values Are Oriented to Be Read From When Using Unidirectional Dimensioning Methods"